BLE vs. GPS Tracking: Key Differences, Costs, Battery Life & Range

Asset shrinkage isn’t just loss. It is profit erosion.

Every misplaced or stolen piece of equipment cuts directly into your margins. Global asset shrinkage from theft, damage, and loss regularly exceeds 1.5 percent of total retail sales. That adds up to billions in lost revenue. Losing even one high-value asset, such as a specialized machine, can mean a five or six-figure replacement cost and weeks of costly downtime. Keeping operations efficient requires real-time visibility into your assets.

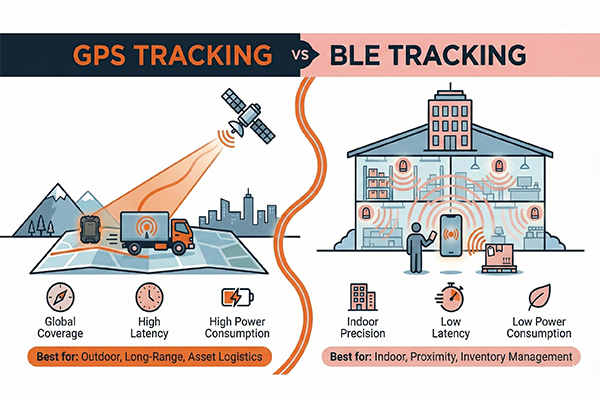

To reduce this financial risk, operations teams often choose between Bluetooth Low Energy (BLE) tracking and GPS tracking. Both can locate assets, but each works differently and carries different long-term costs. Their fit depends entirely on the asset type and use case. BLE trackers can run for one to two years on a single battery, while GPS devices may need charging every few days. Choosing the wrong option can lead to overspending or poor protection for your most critical equipment.

This blog gives you a clear, practical framework to help you choose the right tracking technology and maximize your return on investment.

Defining the Technology: GPS, BLE, and RFID

Before we look at the features, we need to define the technologies. The confusion often lies in understanding how these devices communicate location data.

What is a GPS Tracker?

To understand the difference, we must first answer what a GPS tracker is. GPS relies on a network of satellites orbiting the Earth. A GPS tracker receives signals from at least four of these satellites to calculate its precise coordinates. This process is called trilateration.

The device then uses a cellular connection, such as 4G, LTE, or 5G, to send that location data to your phone or dashboard. It is independent of local devices. However, it usually requires a clear line of sight to the sky and a cellular subscription to transmit the data.

What is BLE Location Tracking?

BLE location tracking works differently. Instead of talking to satellites, a BLE tracker sends out a continuous radio signal or beacon. Nearby smartphones or gateways pick up this signal. If you are within range, your phone tells you where the item is.

If you are out of range, the tracker relies on a community mesh network. This means other users’ phones pick up the signal and anonymously report the location back to you.

The RFID Factor

You cannot talk about BLE asset tracking without mentioning Radio Frequency Identification, or RFID.

- Passive RFID: This is like the sticker on a new pair of jeans or an employee badge. It has no battery and only transmits data when a powerful handheld scanner wakes it up. It is cheap but has a very short range.

- Active RFID: This has a battery and broadcasts a signal. It is similar to BLE but usually requires expensive proprietary infrastructure or readers installed throughout a facility.

RFID is excellent for scanning inventory as it passes through a warehouse door. However, it cannot tell you if your cargo is halfway across the country. That is where GPS and BLE shine.

Quick Comparison: ROI & Capability Matrix

For a strategic summary of the GPS vs Bluetooth tracker decision, review the feature matrix below to see which technology fits your operational budget:

| Feature | BLE (Bluetooth Low Energy) | GPS (Global Positioning System) |

|---|---|---|

| Primary Infrastructure | Short-range Radio Frequency (Beacon) | Satellite Trilateration + Cellular 4G/5G |

| Connectivity Range | 100-400 ft (Gateway Dependent) | Global (Limitless Outdoors) |

| Location Accuracy | High (Indoor / Room-Level) | High (Outdoor), Low (Indoors) |

| Battery Life | 12-36 Months (Energy Harvesting Capable) | Days to Weeks (High Draw) |

| Cost Model | CapEx: Low Hardware Cost ($20-$40) | OpEx: Hardware ($50+) + Monthly Data Subscription |

| Best Use Case | Warehouse Inventory, Tools, Medical Devices | Fleet Vehicles, Cargo Containers, Heavy Machinery |

Critical Feature Analysis: Beyond the Hardware

When analyzing GPS tracker vs bluetooth tracker options for enterprise use, you have to look beyond the plastic tag. You need to evaluate the ecosystem, data integration, and total cost of ownership.

1. Cost Structure & Top Ecosystems

Budget is usually the deciding factor. BLE tracking follows a “buy once” model. You purchase the tag, and you own the data. GPS trackers generally incur a hardware cost plus a recurring monthly subscription fee to cover the cellular data usage required to transmit coordinates to the cloud.

Leading Providers by Category:

- Consumer / Light Use: Chipolo and Tile (Best for keys, wallets, and local proximity).

- Enterprise / Hybrid Solutions: This is where the market splits. Businesses need robust data, not just a beep on a phone.

- GPX (B2B Enterprise): If you need end-to-end supply chain visibility, GPX offers specialized intelligence. They excel in providing backend logistics data, utilizing GPS for long-haul trucking and BLE asset tracking for inventory management inside the warehouse.

- Logistimatics (SMB & Fleet): For easy deployment, Logistimatics provides accessible, user-friendly GPS tracking. Whether it is tracking a fleet of delivery vans or securing expensive media equipment, they offer the “set it and forget it” simplicity that complex enterprise platforms often miss.

2. Range vs. Latency: The Real-Time Factor

This is the most significant differentiator. A BLE tracker is tethered to a gateway. If your tagged tool case is 50 feet away, visibility is instant. However, if your cargo trailer is 10 miles away, you cannot “track” it in real-time unless a gateway passes by. There is latency in BLE updates outside of controlled facilities.

A GPS tracker offers true real-time location. You can watch a vehicle move down a highway on a map, updating every few seconds, regardless of proximity to other devices.

3. Battery Life & Power Efficiency

In the contest of energy efficiency, Bluetooth wins.

- BLE: Because the device only sends out a tiny “advertising packet” periodically, a standard coin-cell battery can last 1-3 years.

- GPS: Communicating with satellites and cellular towers is power-intensive. Most GPS trackers need recharging every few days, though specialized asset trackers (like those from GPX) feature larger batteries and “sleep modes” that extend life to months by limiting updates to once per day.

4. Geofencing & Smart Alerts

Both technologies offer geofencing, but the application differs:

- GPS Macro-Geofencing: Perfect for setting a perimeter around a city or job site. You get an alert when the tracker crosses the boundary (e.g., a rental generator leaving the authorized zone).

- BLE Micro-Geofencing: Used for “separation alerts.” If the BLE tracker moves out of range of the gateway (e.g., a specialized drill left behind at a job site), the system triggers an instant alert to the driver.

5. Private Mesh vs. Public Networks

Consumer tags rely on a “Crowd Find” network (other users’ phones). In a business context, this is unreliable. Enterprise BLE asset tracking relies on a Private Mesh Network. You install gateways in your facilities or trucks (using a GPS tracker as a hub). This creates a secure, private infrastructure that doesn’t rely on public cell phone traffic.

The Verdict: Which Technology Solves Your Problem?

The choice between BLE tracking and GPS comes down to one question: Do you need to know where it is, or where it was?

- Choose BLE Tracking if: You are tracking high-volume assets that stay within a building or yard (tools, pallets, inventory). It is cost-effective, battery-efficient, and precise.

- Choose GPS Tracking if: You are tracking high-value assets that travel long distances (vehicles, shipping containers). The monthly service cost is the price of insurance for global visibility and theft recovery.

The Future is Hybrid: For many businesses, the “Silver Bullet” is a combined approach. Using GPX’s ecosystem, you can track the vehicle via GPS while using BLE asset tags on the individual pallets inside. This guarantees that the truck arrives and the inventory is accounted for.

Frequently Asked Questions (FAQs)

Is there a device that combines both technologies?

Yes. Hybrid Asset Trackers are fast becoming the industry standard. These devices utilize GPS to track the asset during long-haul transit and automatically switch to Bluetooth for “last mile” precision finding when the asset arrives at a warehouse. This provides global visibility without sacrificing indoor accuracy.

Can I track my fleet vehicles with a BLE tracker?

Technically, yes, but it is not recommended for theft recovery. A BLE tracker relies on a nearby gateway or phone to “see” the asset. If a thief drives your truck to a remote area, the tracker goes dark. GPS is the only reliable choice for moving vehicles and theft recovery.

Do GPS trackers require a SIM card?

Yes. Just like a smartphone, a commercial GPS tracker needs a cellular connection (LTE-M, 4G, or 5G) to send location data to your dashboard. This is why professional solutions from companies like GPX or Samsara include a monthly data subscription to guarantee coverage.

How accurate is BLE compared to GPS?

GPS is accurate to within 5-10 meters outdoors but often fails indoors due to signal blockage (“Urban Canyons”). BLE is superior indoors, capable of pinpointing an item to within a few feet (1-3 meters). This makes BLE the top choice for finding specific pallets, tools, or medical devices inside a large facility.

How do I get tracking data into my existing software (ERP)?

This is the key to Asset Intelligence. Enterprise-grade trackers (unlike consumer tags) offer Open API integrations. This allows you to feed location data directly into your existing ERP, SAP, or Fleet Management Software, automating your inventory reporting and eliminating manual data entry.

Is my location data secure from competitors?

Security depends on the network type. Consumer BLE tags (like Tiles) use a public “crowd” network. Enterprise BLE uses a Private Mesh Network, meaning your data is encrypted and only visible to your gateways and your team, ensuring total operational secrecy.

How often do I need to replace batteries?

It depends entirely on the technology. BLE tags are extremely efficient and can run for 2-5 years on a single coin-cell battery. Real-time GPS trackers consume much more power and typically require recharging every few days or weeks, unless they are hardwired directly into the vehicle’s power source.