Optimize Production. Secure Assets. Maximize Output.

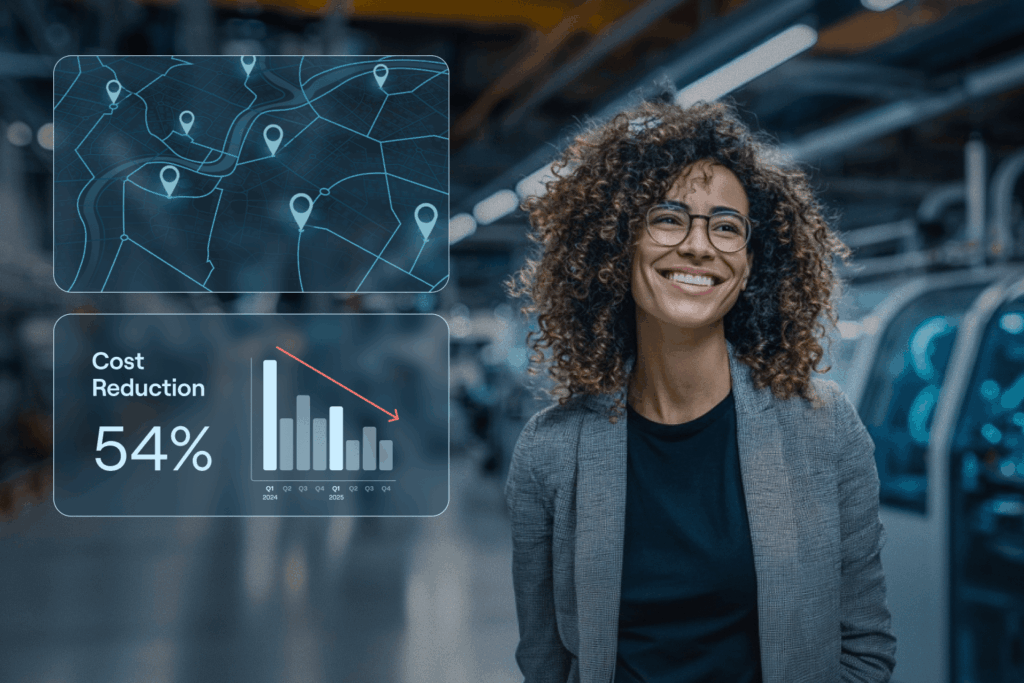

Conquer manufacturing challenges with GPX Intelligence. We deliver operational efficiency and complete visibility through advanced asset tracking manufacturing, IoT, SaaS, and our groundbreaking AI supply chain agent, Scout. Gain end-to-end control, reduce costs, enhance productivity, and unlock actionable supply chain insights from day one. Future-proof your manufacturing with GPX.

A trusted partner to the world's biggest companies

Secure assets with real-time location data from industrial GPS trackers, geofencing, & instant alerts for superior asset protection and theft prevention.

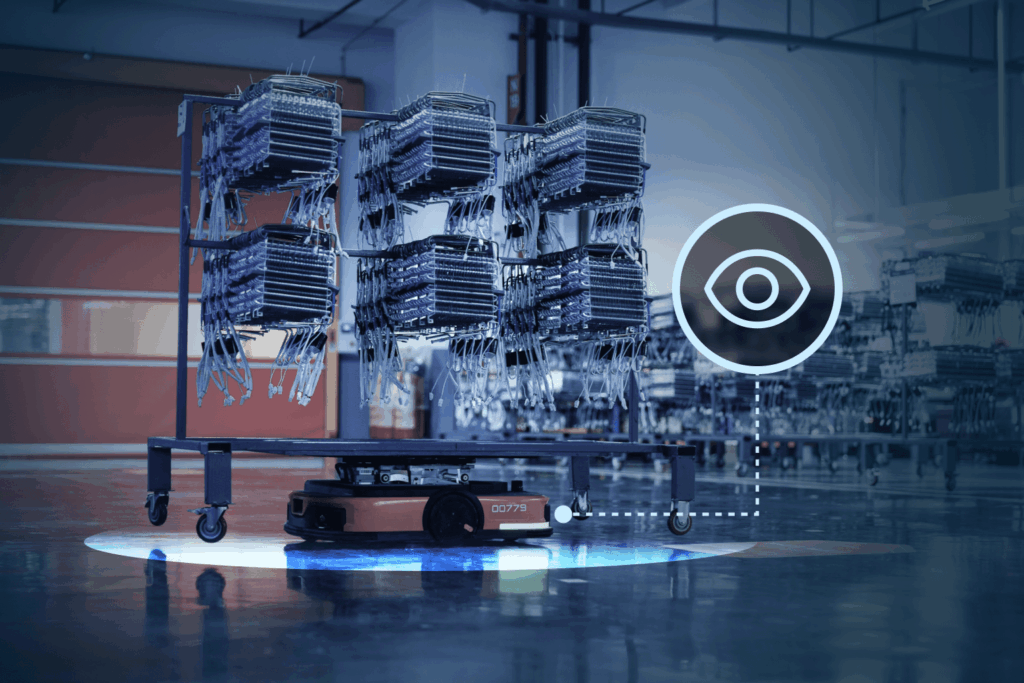

Gain complete manufacturing supply chain visibility. Monitor parts to delivery with comprehensive end-to-end tracking for seamless logistics.

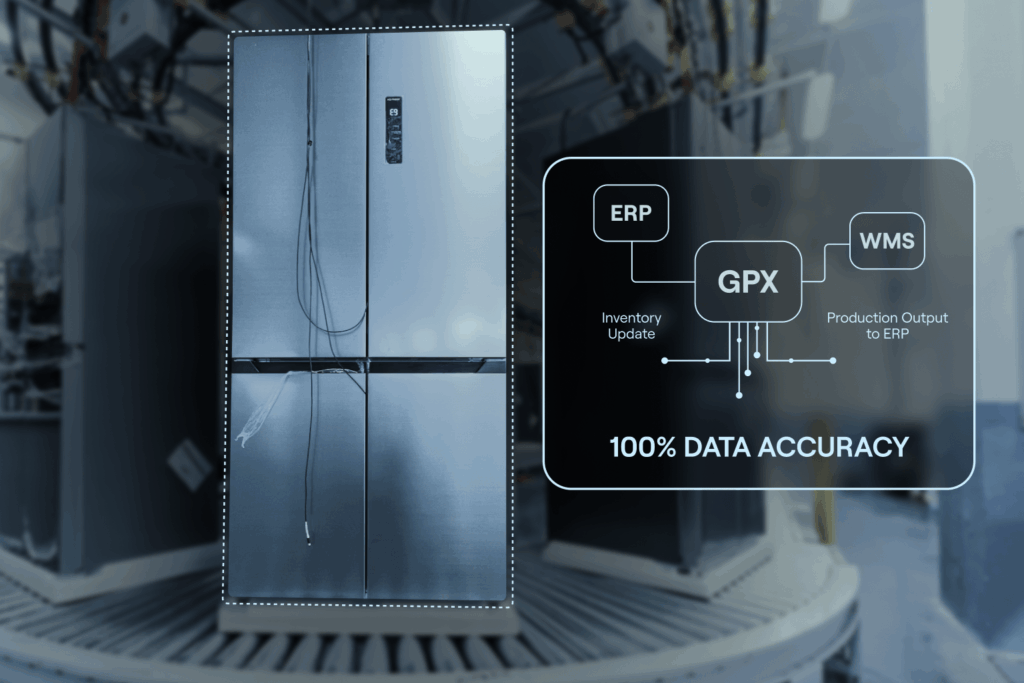

Unify operations. Our platform offers seamless integration with your ERP, WMS, TMS & more for total visibility and control.

Eliminate bottlenecks & slash downtime. Real-time production tracking system monitoring optimizes flow for maximum production efficiency.

Turn data into profit. Leverage reporting, analytics, & our AI supply chain agent, Scout, for optimized operations and actionable supply chain insights.

Sensitive parts demand more than location. Our industrial GPS trackers monitor temperature tracking, humidity, shock tracking, and tamper tracking events in real-time, providing instant insight into environmental or handling risks during storage and transit.

Reliable, Cost-Effective Protection: Secure sensitive goods with affordable, robust tracking that actively monitors environmental conditions and potential tampering.

Intuitive Bird's-Eye View Dashboard: Gain immediate visibility into asset conditions and alerts through a user-friendly interface, simplifying complex environmental monitoring for assets.

Customizable Geofence Alerts: Define specific geographic zones and receive instant notifications for entries, exits, or unauthorized movements, enhancing asset protection.

The AssetTrack boasts an exceptional 10-year battery life, eliminating installation hassles. Simply place this BLE-enabled GPS tracker on your asset and gain immediate visibility.

Hardware + Service Included: Comprehensive solution out of the box.

Zero Installation Costs: "Place and trace" simplicity saves time and resources.

Reliable 4G/5G Tracking: Dependable connectivity anywhere for your asset tracking manufacturing needs.

The Asset Track Mini is a compact, reliable, small-profile mini GPS tracker ideal for construction asset tracking and other valuable manufacturing assets where space is a premium.

Up to 7 Years Battery Life: Long-lasting performance for extended deployments.

Hardware + Service Included: Get everything you need to start tracking.

Small & Versatile with Universal Coverage: Discreet design with broad network reach.

Stop Losses, Maximize Efficiency: Advanced Asset Tracking for Manufacturers

Achieve real-time visibility of returnable container tracking and inventory across your manufacturing supply chain with mesh-networked tracking. Monitor movement across suppliers, warehouses, production lines, and transit.

Reduce Shrinkage: Utilize geofence alerts and dwell time monitoring to minimize loss and prevent costly delays.

Protect High-Value Assets: Track the exact location and condition of raw materials, machinery, and finished goods using durable, low-maintenance devices with environmental, shock, and tamper tracking.

Streamline Inventory: Enhance inventory tracking from production to delivery for a leaner, more efficient operation.

Geofencing Alerts. Stay in Control.

Track materials, machinery & goods with our advanced GPS and BLE trackers. Get real-time location, geofence alerts & comprehensive environmental monitoring for assets.

Safeguard Sensitive Assets: Monitor temperature tracking, humidity, shock tracking, & tamper detection to protect components and reduce downtime.

Versatile Hardware: Choose disposable or durable devices (BLE-enabled GPS trackers, Mini GPS trackers) for all shipments & high-value assets.

Maintain Supply Chain Control: Gain critical visibility to streamline production, ensure asset protection, and manage your supply chain effectively.

GPX Intelligence offers more than asset location; our sophisticated manufacturing tracking systems provide deep insights into your production tracking system and overall tracking manufacturing processes. Optimize workflows, pinpoint inefficiencies, and boost output with real-time data.

Track components and sub-assemblies through each workstation.

Monitor cycle times and identify deviations from standards.

Gain visibility into machine uptime, downtime, and OEE.

Visualize material flow and spot bottlenecks instantly.

Automate data collection for process improvement.

Ensure Just-in-Time (JIT) material delivery.

Link tracking data with quality assurance checkpoints.

Maintain detailed audit trails for compliance and recalls.

Quickly isolate affected batches if quality issues arise.

Equip operators and supervisors with actionable information.

Reduce manual data entry, freeing up time for value-added tasks.

Safeguard your critical equipment and sensitive materials with our advanced high-value goods tracking technology. Our solutions provide unparalleled security and insight:

Our solutions provide:

1

Real-Time Alerts: Instant notifications for critical events, movement, or condition changes.

2

Detailed Location History: Comprehensive audit trails for complete asset visibility.

3

Tamper-Proof Data: Secure, reliable information you can trust for decision-making.

4

AI-Powered Risk Analysis: Proactively identify and mitigate potential threats to your assets with Scout AI.

Replace time-consuming, error-prone manual processes with our sophisticated automated tracking solutions. Boost productivity and data integrity across your manufacturing operations:

Our automated tracking solutions:

1

Streamline Operations: Optimize workflows and reduce bottlenecks with automated data capture.

2

Reduce Manual Effort: Free up your team to focus on value-added tasks, not manual tracking.

3

Improve Data Accuracy: Eliminate human error for more reliable operational insights.

4

Seamless ERP & WMS Integration: Connect effortlessly with your existing systems for unified control.

Transform your manufacturing with Scout AI, a game-changing tool supercharging actionable supply chain insights. Scout harnesses your IoT data, amplifying it with the full power of AI LLMs for manufacturing to revolutionize how you operate.

Surface Anomalies Instantly: Detect critical issues and deviations in real-time before they impact your bottom line.

Streamline Manufacturing Operations: Identify inefficiencies and receive intelligent recommendations to optimize workflows and boost productivity.

Become Predictive, Not Reactive: Anticipate future challenges, predict maintenance needs, and seize opportunities, improving your business proactively.

We’re pioneering the future with location-enabled smart factories and warehouses. GPX drives the industry forward through its innovative GPS and BLE solutions that reduce infrastructure overhead. Our BLE-enabled GPS devices act as a central hub to report tagged asset locations both inside and outside your facility, enabling true IoT in manufacturing.

More than just location data

Gain access to powerful analytics and reporting tools that help you:

1

Real-Time Inventory Visibility Across Your Network

2

Optimized Warehouse Operations

3

AI-Driven End-to-End Supply Chain Insight with Scout

Case Study

See how our customers have used our tracking solutions to improve their supply chain operations, reduce costs, and enhance customer satisfaction.

Your Questions About Manufacturing Visibility and Tracking Answered

Frequently asked questions about Manufacturing Asset Tracking and Manufacturing Visibility

The optimal industrial GPS tracker for your manufacturing needs depends on factors like asset type, environment, and required battery life. GPX Intelligence offers a range of solutions, from compact Mini GPS trackers for tools and equipment to long-life BLE-enabled GPS trackers for larger assets and returnable container tracking. Key features for superior manufacturing visibility include real-time location, geofencing, and environmental sensors, all enhanced by our Scout AI platform for predictive insights.

Our manufacturing tracking systems are crucial for theft prevention and loss reduction. They provide real-time location of all tracked assets, from raw materials to finished goods. Geofencing creates virtual boundaries, triggering instant alerts for unauthorized movements. Tamper detection and shock tracking add further layers of security for high-value goods tracking.

Yes, significantly. GPS tracking provides precise, real-time location data for raw materials, work-in-progress (WIP), and finished goods, drastically improving manufacturing inventory management. This reduces search times, minimizes misplacements, prevents stockouts or overstocking, and supports lean manufacturing principles. When combined with Scout AI, it delivers powerful actionable supply chain insights.

Essential features for industrial GPS trackers in manufacturing include real-time location updates, robust geofencing capabilities, long battery life suitable for your assets, durable hardware to withstand industrial environments, and relevant environmental sensors (e.g., temperature tracking for sensitive materials, shock tracking for fragile items). For a complete solution, look for platforms offering manufacturing analytics, AI-powered risk analysis, and seamless integration, like GPX Intelligence with Scout AI.

GPS tracking enhances manufacturing supply chain visibility from end to end. It allows you to monitor raw material inbound shipments, track components through production (production tracking system), manage finished goods in warehouses, and follow products through distribution channels. This leads to reduced delays, optimized logistics, improved asset tracking manufacturing processes, and a more resilient supply chain.