Trusted by Fortune 500 Automotive & Heavy Equipment OEMs

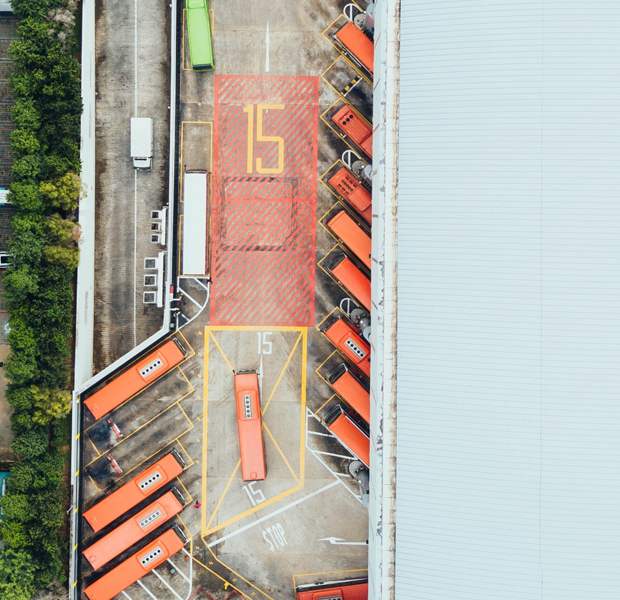

Gain real-time visibility of reusable containers, high-value components, and critical shipments across automotive, heavy equipment, and agricultural OEM operations. Our proven tracking platform prevents losses, strengthens supplier accountability, and ensures on-time delivery—powered by enterprise-grade GPS and BLE technology.

A trusted partner to the world's biggest companies

✅ 95% recovery rate for reusable containers and high-value components

✅ Instant alerts for missing items, unauthorized movement, and supplier delays

✅ Supplier accountability with detailed audit trails and performance reporting

✅ 5X ROI through reduced losses, eliminated expedited shipping, and improved efficiency

Achieve 95% recovery rate for reusable containers and high-value components. Monitor thousands of OEM assets globally with enterprise-grade GPS tracking on an intuitive dashboard.

Eliminate supply chain blind spots with real-time tracking from vendor to production line. Cut costs and prevent delays with complete end-to-end visibility of critical parts and shipments.

Connect instantly with SAP, Oracle, and 50+ ERP systems via our robust API. Unify your supply chain data for complete visibility and streamlined operations across all platforms.

Protect millions in OEM investments from theft, loss, and supplier misuse. Real-time alerts and location intelligence safeguard your valuable containers and components.

Automate container returns and prevent costly stockouts with intelligent tracking. Real-time inventory updates eliminate manual processes and reduce supplier accountability issues.

Generate 5X ROI through reduced losses, eliminated expedited shipping, and improved supplier efficiency. Streamline operations to boost margins and competitive advantage.

Safeguard high-value OEM components and sensitive materials with tracking devices engineered for industrial environments. Our advanced sensors deliver real-time alerts for temperature fluctuations, humidity changes, shock events, and unauthorized access—preventing quality issues, ensuring compliance, and protecting your investment from vendor to production line.

Deploy rugged, waterproof trackers on reusable containers, equipment racks, or vehicles with confidence. Up to 10-year battery life eliminates maintenance concerns while customizable alerts and automated reporting maximize visibility without requiring individual asset tagging—saving time and reducing operational complexity.

Enterprise-grade reliability with 99.9% uptime guarantee

Complete environmental monitoring for quality assurance compliance

Zero-maintenance operation with decade-long battery performance

The AssetTrack delivers maximum visibility for reusable containers, equipment racks, and high-value components. Perfect for OEMs managing complex closed-loop systems with multiple suppliers and facilities.

10-year battery life - deploy and forget maintenance

Zero installation required - attach and start tracking instantly

Indoor/outdoor tracking with BLE + GPS technology

The AssetTrack Mini provides enterprise-grade tracking in a compact form factor. Ideal for smaller components, tools, and assets where space is limited but visibility is critical.

Up to 7 years battery life with reliable performance

Hardware + service included - no hidden costs

Compact design fits on any asset or container

Achieve 95% Recovery Rates. Eliminate Million-Dollar Losses.

Prevent costly delays and eliminate container losses with GPS tracking that delivers actionable intelligence across your entire supply chain. Our platform helps leading OEMs achieve 95% recovery rates while reducing expedited shipping costs by millions annually.

Key Results:

✅ 95% container recovery rate vs. 60% industry average

✅ 5X ROI within 60 days through reduced losses and improved efficiency

✅ Eliminate expedited shipping with proactive delay prevention

✅ Strengthen supplier accountability with automated reporting

Enable your supply chain team to track containers, monitor return rates, and optimize distribution routes from raw material sourcing to final delivery. Make data-driven decisions that cut waste, lower costs, and ensure on-time, sustainable operations.

Instant Alerts. Complete Protection. Zero Compromise.

Safeguard sensitive OEM components and critical materials with advanced tracking that monitors location, temperature, humidity, shock, and unauthorized access. Prevent quality failures and ensure compliance with real-time alerts and automated documentation.

Advanced Protection:

✅ Prevent quality failures with environmental monitoring

✅ Instant tamper alerts protect against theft and misuse

✅ Automated compliance reporting streamlines quality assurance

✅ Custom alert thresholds for your specific component requirements

Choose from disposable trackers for short-term shipments or rugged, long-term devices for permanent asset monitoring. From returnable containers to fleet equipment, our solutions provide the visibility OEMs need to secure assets and streamline operations.

Leading OEMs lose millions annually to container theft, component misplacement, and supply chain blind spots. Our Fortune 500 clients achieve 95% recovery rates and 5X ROI by implementing real-time GPS and BLE tracking across their global operations. Transform supply chain visibility into competitive advantage with solutions designed specifically for complex OEM environments.

The Challenge: OEMs lose $2-5 million annually on unreturned or stolen reusable containers, forcing expensive replacements and disrupting supplier relationships.

Our Solution:

Proven Results:

✅ 95% container recovery rate (vs. 60% industry average)

✅ $2M+ annual savings in replacement costs for automotive clients

✅ 50% reduction in supplier disputes over missing containers

✅ Enhanced supplier relationships through transparent accountability

Implementation: Deploy tracking devices on high-value containers with zero installation required. Monitor container movements, set custom return deadlines, and receive instant alerts for missing assets. Integration with your ERP system provides automated reporting and seamless workflow management.

Case Study Preview: Major automotive manufacturer achieved 95% recovery rate, saving $2.1M annually in container replacement costs while strengthening supplier partnerships.

The Challenge: Lack of real-time shipment visibility leads to production delays, expedited shipping costs, and customer dissatisfaction when critical components arrive late.

Our Solution:

Measurable Impact:

✅ 60% reduction in production delays caused by late shipments

✅ Eliminate expedited shipping costs through proactive management

✅ 25% improvement in on-time delivery performance

✅ Enhanced customer satisfaction with reliable delivery commitments

Key Features:

Real-World Application: Heavy equipment OEM reduced production delays by 60% and eliminated $800K in expedited shipping costs through proactive shipment monitoring.

The Challenge: Traditional tracking requires tagging every individual item, creating overwhelming complexity and high costs for OEMs managing thousands of components and assets.

Our Solution:

Operational Benefits:

✅ 90% cost reduction compared to individual item tracking

✅ Simplified deployment with minimal hardware requirements

✅ Scalable approach grows with your operations

✅ Flexible granularity – track what matters most

Smart Tracking Strategies:

Technology Advantage: Our BLE mesh network creates “smart zones” where a single GPS tracker can provide location context for dozens of nearby assets. This revolutionary approach delivers comprehensive visibility at a fraction of traditional tracking costs.

Success Example: Agricultural OEM reduced tracking costs by 85% while maintaining complete visibility over 10,000+ seasonal components using smart zone monitoring.

Safeguard high-value OEM components and critical assets with tracking technology engineered for industrial environments. Our Fortune 500 clients prevent costly quality failures and achieve 95% asset recovery through real-time monitoring and predictive risk analysis.

Advanced Protection Delivers:

1

Instant Quality Alerts - Prevent component damage with real-time temperature, humidity, and shock monitoring

2

Complete Asset History - Maintain chain of custody documentation and compliance reporting for audit trails

3

Tamper-Proof Security - Detect unauthorized access and theft attempts with immediate notifications

4

AI-Powered Risk Analysis - Predict potential failures and optimize asset management with machine learning insights

Replace error-prone manual tracking with intelligent automation that integrates seamlessly with your existing systems. Leading OEMs reduce operational costs by 25% and achieve 5X ROI through streamlined processes and enhanced data accuracy.

Automated Excellence Provides:

1

Streamlined Operations - Eliminate manual data entry and reduce tracking overhead by 90%

2

Zero Manual Effort - Automatic location updates and inventory synchronization across all systems

3

99.9% Data Accuracy - Real-time synchronization prevents errors and ensures reliable reporting

4

Instant ERP Integration - Connect with SAP, Oracle, and 50+ systems via robust APIs for unified visibility

Transform your manufacturing with Scout AI, a game-changing tool supercharging actionable supply chain insights. Scout harnesses your IoT data, amplifying it with the full power of AI LLMs for manufacturing to revolutionize how you operate.

Surface Anomalies Instantly: Detect critical issues and deviations in real-time before they impact your bottom line.

Streamline Manufacturing Operations: Identify inefficiencies and receive intelligent recommendations to optimize workflows and boost productivity.

Become Predictive, Not Reactive: Anticipate future challenges, predict maintenance needs, and seize opportunities, improving your business proactively.

Transform supplier accountability from a constant challenge into a competitive advantage. Leading OEMs reduce supplier disputes by 70% and achieve 95% container return rates through transparent tracking, automated reporting, and seamless collaboration tools. Share real-time visibility with suppliers while maintaining complete control over your valuable assets.

More than just location data

Gain access to powerful analytics and reporting tools that help you:

1

Identify trends

2

Optimize performance

3

Make data-driven decisions

Case Study

See how our customers have used our tracking solutions to improve their supply chain operations, reduce costs, and enhance customer satisfaction.

Your Questions About OEM Visibility and Tracking Answered

Frequently asked questions about the OEM Tracking