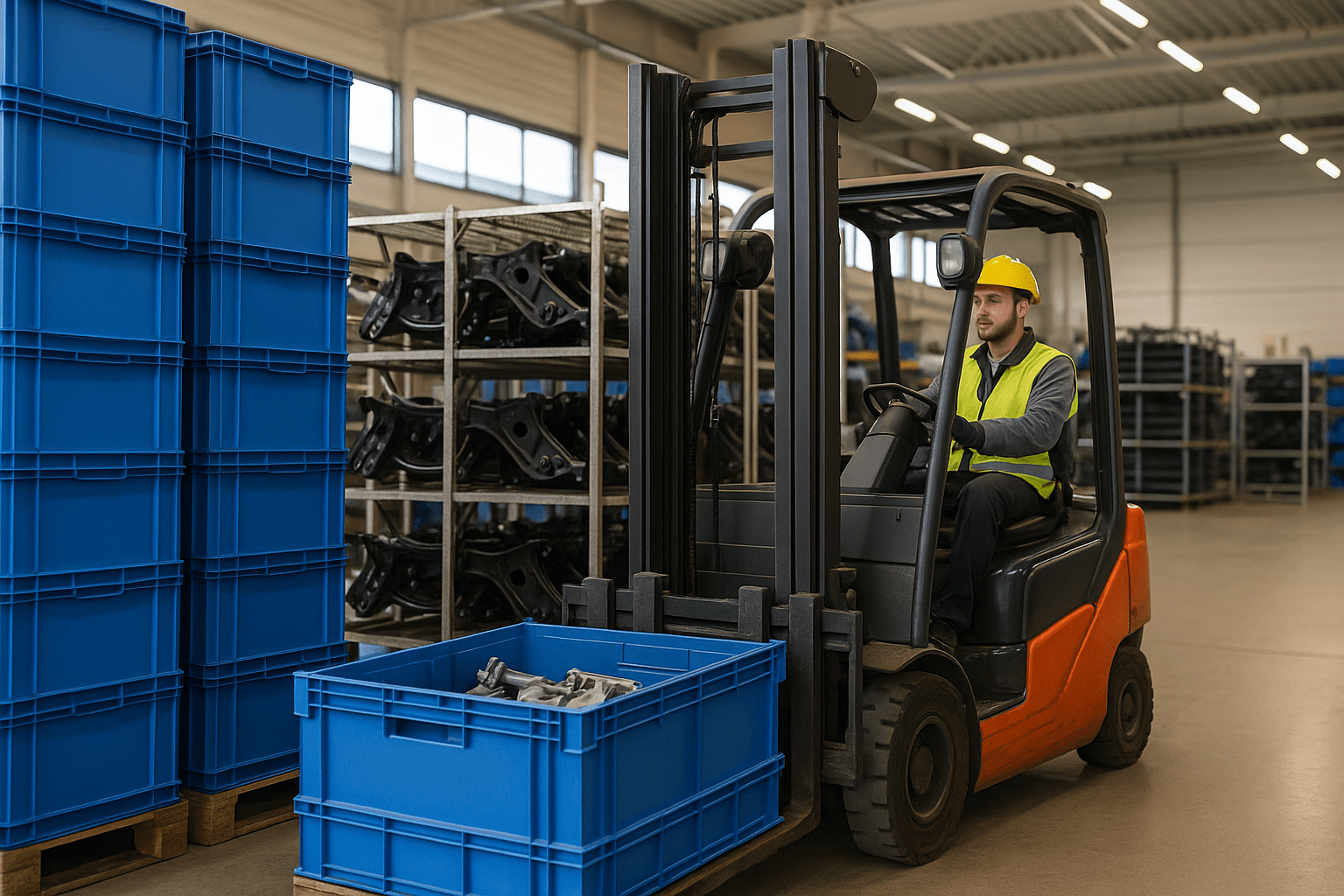

From Pallet to Profit: Your Assets, Optimized and Secure.

Pallets, crates, totes, and dunnage move through every stage of the supply chain, from the warehouse to the customer, often facing blind spots and inefficiencies that cost businesses millions in lost assets and wasted labor. Our IoT-enabled pallet tracking system delivers real-time cargo visibility, eliminates wasteful searches, safeguards your investments, and maximizes asset availability. By enhancing operational efficiency and ensuring every shipment is accounted for, you can transform logistics challenges into strategic advantages while achieving substantial cost savings across your entire network.

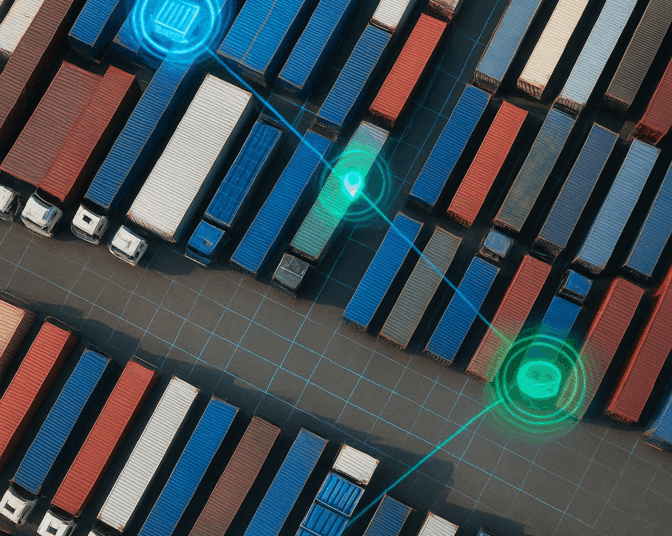

Track Every Pallet in Transit. Control It in Real Time.

Gain complete control over your palletized assets with real-time pallet tracking solutions.

Our system provides up-to-the-minute location updates for every pallet, crate, and tote, whether it’s moving through a busy warehouse or staged in a remote yard.

We leverage a strategic blend of GPS tracking for wide-area visibility, BLE tracking for high-accuracy indoor location, and RFID solutions for automated checkpoints. This powerful combination eliminates blind spots, providing precise asset location and enhanced inventory control throughout your warehouse logistics and shipping processes.

Every Crate, Every Tote, Always Accounted For.

Our pallet tracking solutions support every asset type, from standard pallets to crates and specialized tote containers (Orbis, etc.), anywhere, anytime.

We deploy a range of hardware, including disposable trackers for single-journey logistics and reusable trackers for continuous use in a closed-loop system.

For permanent assets, long-range and short-range trackers offer flexible deployment. Proactively address disruptions and safeguard assets with features like instant real-time alerts, customizable geofencing, and vital shock, temperature, and humidity tracking, enabling proactive management of your valuable reusable assets.

A trusted partner to the world's biggest companies

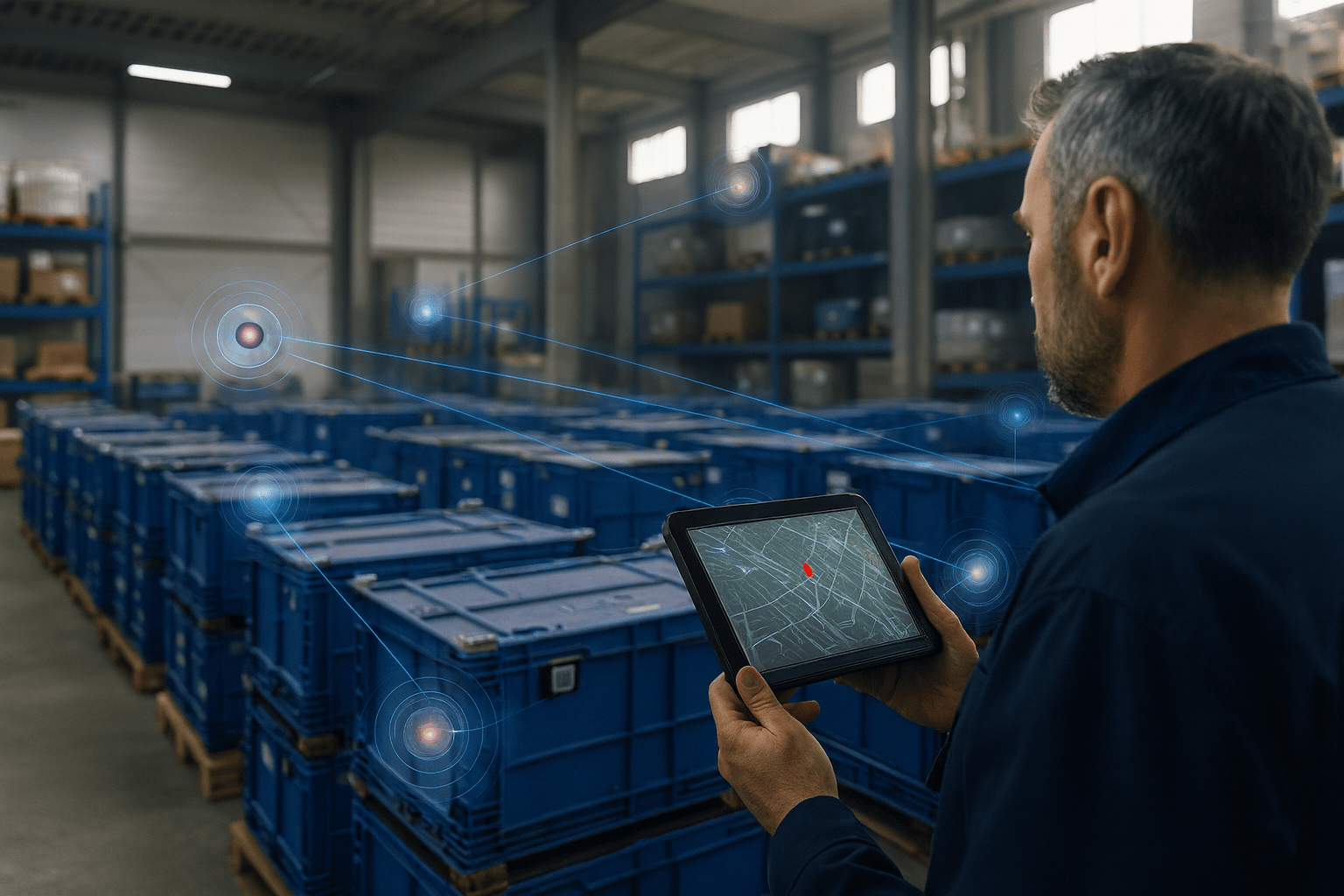

Effectively managing high volumes of pallets, crates, and dunnage presents persistent operational and financial hurdles for businesses. These challenges often lead to increased costs, inefficiencies, and reduced overall profitability. Our advanced pallet tracking system is designed to transform these pain points into strategic advantages by providing a single platform for complete control and visibility.

The frequent disappearance or misplacement of pallets and crates leads to significant and often underestimated financial drain. Our solution provides real-time location tracking and smart geofencing for every palletized unit, sending instant alerts for unauthorized movement. This deters asset theft and enables swift asset recovery, drastically reducing asset shrinkage and replacement costs for your valuable reusable assets.

Relying on manual tracking for thousands of pallets and totes is prone to human error, resulting in widespread data inaccuracy and significant inventory discrepancies. Our automated solutions leverage RFID and BLE tracking to digitize workflows, eliminating human error. This creates a unified data ecosystem with a single source of truth, ensuring precise inventory accuracy for all your heavy-duty and reusable plastic containers, streamlining reconciliation efforts and improving labor efficiency.

Operational bottlenecks and wasted resources are a major challenge, with suboptimal utilization of pallets and crates leading to idle assets. Our system provides actionable insights into cycle times and dwell times, enabling optimized flow and proactive empty container management. This streamlines logistics processes, boosts container throughput, and dramatically improves asset turnover, transforming inefficient pooling into peak operational efficiency across your entire supply chain.

Supply chain visibility gaps create blind spots and accountability issues across multi-party logistics. Our advanced pallet tracking solutions provide end-to-end visibility across the entire supply chain, from your warehouse to final destination. This comprehensive insight, leveraging a blend of GPS and BLE tracking technologies, allows you to streamline operations and respond swiftly to disruptions, fostering robust supply chain resilience by ensuring you always know the precise location and status of your assets.

Ensuring quality control and the integrity of goods on pallets and crates is critical, especially for sensitive products. Our solutions offer condition monitoring via sensors for temperature tracking, humidity tracking, and shock tracking. This proactive approach prevents damage, ensures regulatory compliance, and safeguards product integrity from the warehouse to its destination.

Gain truly intelligent pallet and crate management. Our advanced tracking technology safeguards your pallet and tote pool, optimizes its movement, and provides critical insights into its asset lifecycle, ensuring unparalleled peace of mind across your closed-loop logistics system.

Our solutions provide:

1

Instant Security Alerts: Get real-time alerts for unauthorized pallet, crate, or dunnage activity.

2

Complete Movement History: Full audit trail from dispatch to return.

3

Secure Devices & Data: Rugged, discreet trackers protect data integrity.

4

AI-Powered Insights: Predict pallet and tote demand and risk with AI.

End the struggle with manual pallet and crate reconciliation. Our automated pallet management solutions streamline pallet and tote processes and dramatically boost operational efficiency. By eliminating manual pallet tracking tasks, you'll gain a unified view of your dunnage and container ecosystem through seamless digital integration with RFID and BLE tracking systems.

Our automated tracking solutions:

1

Streamlined Workflow: Simplify pallet handling and reduce manual errors.

2

Improved Accuracy: Automate tracking for precise pallet and tote visibility.

3

Smarter Decisions: Leverage real-time data for quicker, informed actions.

4

Easy Integration: Seamlessly connect with your ERP and WMS systems.

Eliminate: data silos

Enable: better decision-making

Enhance: operational efficiency

Improve: collaboration

Provide: a holistic view of your supply chain to your team

Disconnected systems create information gaps and inefficiencies in pallet and tote management. Our tracking solutions are engineered for deep, seamless integration with your ERP, WMS, and TMS. This creates a truly unified pallet data ecosystem, eradicating data silos and providing a single, trustworthy source of truth for all your critical pallet and dunnage information, including data from fixed GPS tracker deployments.

More than just location data

Gain access to powerful analytics and reporting tools that help you:

1

Identify trends

2

Optimize performance

3

Make data-driven decisions

Case Study

See how our customers have used our tracking solutions to improve their supply chain operations, reduce costs, and enhance customer satisfaction.

Your Questions About Pallet Tracking Answered

Frequently asked questions about Pallet, Crate, Tote, Dunage, and Container Management

Battery life for our trackers is highly configurable and depends on the device type and reporting frequency. Disposable trackers typically last from 2.5 weeks to 2 months, while reusable trackers can last from 2.5 weeks up to 10 years and are designed to be recharged or have their batteries easily replaced. All devices use power-efficient technology with adjustable reporting rates, allowing you to choose long-range reporting for in-transit visibility or short-range reporting for extended battery life in warehouse environments.