GPS Tracking for the Construction Industry: Optimize Operations & Security

Construction is one of America’s largest industries, yet it faces persistent challenges, notably equipment theft. According to the National Equipment Register (NER), construction equipment theft surpassed $1 billion in losses in 2023, reflecting a rising and alarming trend. Despite enhanced security measures, the recovery rate remains low, hovering between 21–22%, highlighting the urgent need for effective theft prevention and recovery strategies.

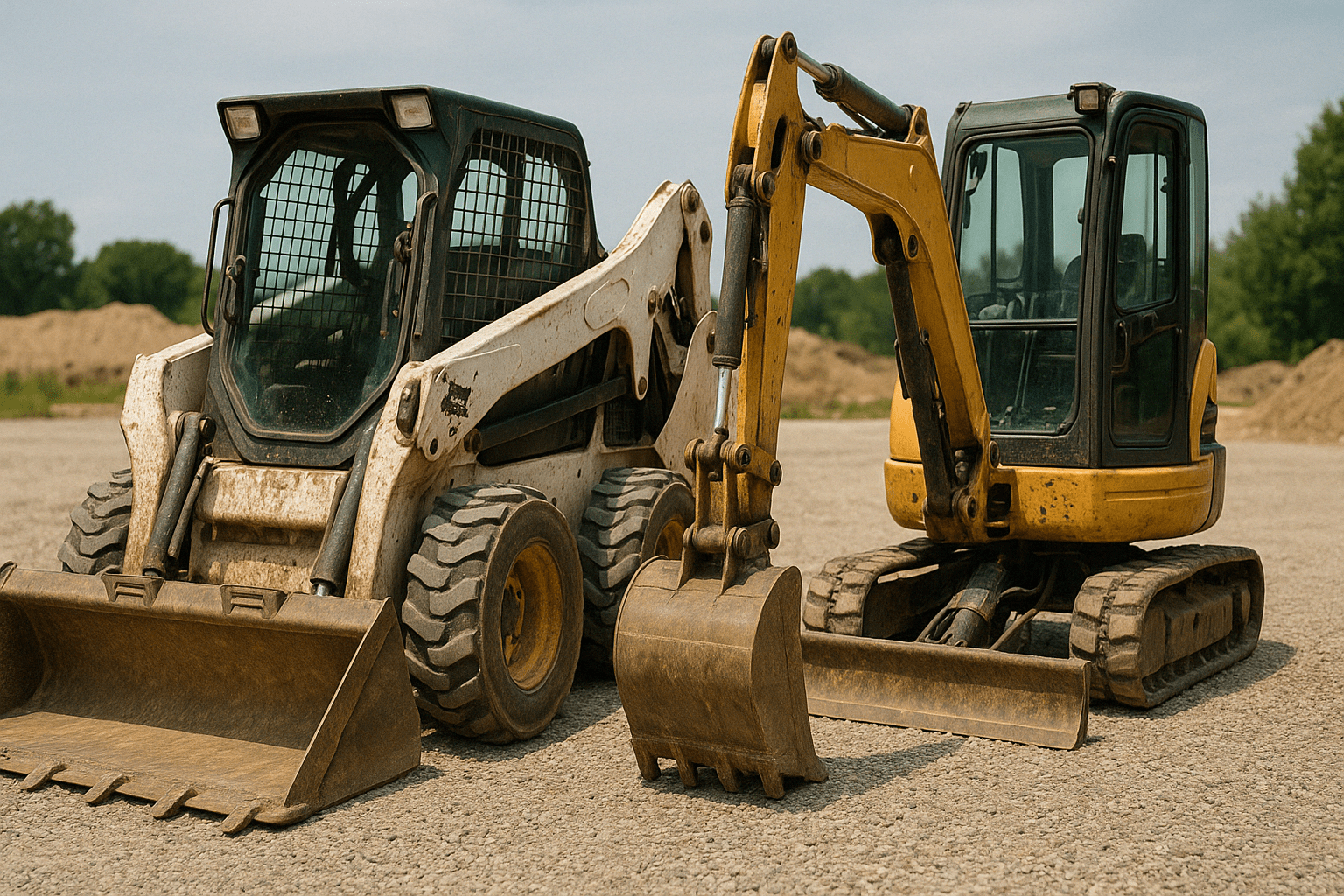

Losses from theft don’t stop at replacement costs—they ripple into project delays, increased labor expenses, penalty fees, and rising insurance premiums, as well as the cost of replacement. In states with significant construction activity, such as Texas, Florida, California, and Georgia, the situation is even more severe. The theft of a single critical machine like a skid steer loader or mini excavator can halt work for weeks, leading to significant financial losses from project delays, increased labor expenses, penalty fees, and rising insurance premiums.

Smarter Site Management Starts with Real-Time Visibility

In the demanding and complex environment of construction, managing multiple job sites efficiently requires precise coordination of people, assets, and time. From heavy machinery to specialized tools, effective asset management is crucial for maintaining productivity and profitability.

GPS tracking technology delivers powerful real-time insights, empowering construction managers with visibility into the precise location and operational status of all assets. With accurate data, managers can make proactive, informed decisions that enhance site efficiency and streamline project management.

Common Targets for Construction Equipment Theft

Certain types of construction equipment consistently rank as high-risk targets due to their high resale value and ease of transport. Among the most commonly stolen items are:

- 🚜 Skid steer loaders

- 🏗️ Mini excavators

- 🔋 Towable generators

- 🚛 Utility trailers

- 🚜 Compact tracked loaders

- 🌿 Commercial mowers

- 🚜 Backhoe loaders

- 🔧 Welder generators

- 💡 Light towers

- ❄️ HVAC units and construction materials

The mobility and marketability of these assets make them particularly attractive to thieves, emphasizing the need for robust tracking and recovery solutions.

Enhancing Security Through GPS Tracking

Traditional security methods like fences, lighting, and onsite personnel, although important, often fall short against determined thieves. GPS tracking systems add a critical layer of defense by offering proactive monitoring capabilities and real-time alerts.

🚨 Immediate Theft Alerts & Real-Time Monitoring

GPS trackers provide continuous monitoring of assets, alerting managers instantly if equipment is moved or operated without authorization. This enables swift intervention, significantly reducing the likelihood of equipment being stolen or misused. Real-time location data ensures that assets, whether parked overnight or actively used during the day, remain secure and within designated areas.

🎯 Effective Asset Recovery

If equipment theft occurs, GPS trackers dramatically increase the chances of recovery. By pinpointing exact locations, law enforcement can quickly locate and recover stolen assets, minimizing downtime and financial losses. Data from LoJack Corporation highlights the effectiveness of GPS technology, having recovered millions of dollars’ worth of equipment annually through tracking systems.

Operational Benefits of GPS Tracking in Construction

Beyond security, GPS tracking technology offers substantial operational benefits, helping construction companies streamline daily activities, enhance productivity, and reduce operating costs.

⚙️ Improved Equipment Utilization and Maintenance

GPS trackers not only track location but also monitor essential metrics such as engine runtime hours and equipment usage patterns. By collecting accurate data, construction managers can better balance workloads, reduce idle time, and optimize maintenance schedules, preventing unexpected breakdowns and extending the operational lifespan of valuable machinery.

Ruggedized GPS trackers specifically designed for harsh construction environments ensure reliable operation, even under extreme conditions like rain, dust, temperature fluctuations, and constant vibration.

🚛 Advanced Fleet Management and Crew Coordination

Efficient fleet management and crew coordination are essential for keeping multiple construction projects running smoothly. Real-time GPS tracking allows fleet managers to monitor vehicle locations, optimize routing and scheduling, and improve driver accountability.

Geofencing technology further enhances operational efficiency by creating virtual boundaries around job sites. Managers receive instant notifications when equipment or vehicles enter or exit predefined zones, ensuring optimal asset allocation and improving project timelines.

📜 Strengthening Regulatory Compliance and Record-Keeping

Accurate record-keeping is essential not only for equipment management but also for regulatory compliance and insurance purposes. GPS tracking systems automatically document precise location histories, usage data, and maintenance records. This helps construction firms comply with regulatory requirements, facilitate insurance claims, and streamline asset management processes.

The National Insurance Crime Bureau (NICB) emphasizes the importance of detailed asset records, including serial numbers and photographs. GPS tracking systems simplify this task, automating the creation of comprehensive asset documentation.

Strategic Implementation: Choosing the Right GPS Tracking Solution

When selecting a GPS tracking solution for construction applications, it’s crucial to consider durability, accuracy, ease of integration, and customer support. Ideal GPS tracking solutions should offer:

- 🛡️ Durable Hardware: Weather-resistant, rugged devices suitable for challenging construction environments.

- 🚨 Real-time Alerts: Immediate notifications for unauthorized asset movement or operational anomalies.

- 📍 Geofencing Capabilities: Virtual perimeter setup to manage asset movement effectively.

- 🖥️ Centralized Platform: User-friendly dashboards for seamless operational oversight across multiple sites.

- 🤝 Customer Support: Accessible expert support to ensure smooth implementation and troubleshooting.

![]()

GPX Intelligence: Your Partner in Construction GPS Tracking

GPX Intelligence specializes in delivering comprehensive GPS tracking solutions tailored specifically to the demanding needs of the construction industry. With robust hardware designed to endure harsh job site conditions and intuitive software for effortless asset monitoring, GPX Intelligence enables construction businesses to enhance security, improve operational efficiency, and protect their bottom line.

By integrating GPS tracking into your construction management strategy, you can proactively address the challenges of equipment theft, optimize fleet and asset utilization, and ensure regulatory compliance, ultimately driving higher productivity and profitability.

Ready to take control of your construction operations and secure your valuable assets? Contact GPX Intelligence today for p

Frequently Asked Questions: Construction GPS Tracking

Are GPS trackers always active on construction equipment?

Not always. Trackers can be configured to activate during specific conditions—like engine startup, geofence movement, or scheduled intervals—depending on your operational needs. This ensures efficient power usage while maintaining critical visibility when it matters most.

How does GPS tracking actually improve job site security?

GPS tracking gives you 24/7 visibility into your equipment’s location and alerts you instantly if assets move unexpectedly. With geofencing and tamper alerts, you’re notified in real time, helping you stop theft before it happens or recover assets quickly if they go missing.

Where are GPS trackers usually installed on construction equipment?

Trackers are typically installed in discreet, secure locations such as under the hood, inside the cab, behind protective panels, or mounted to the chassis. These spots ensure reliable signal strength while helping prevent tampering or removal.

Can GPS tracking help manage a construction fleet more efficiently?

Absolutely. From real-time location updates to route optimization and driver accountability, GPS tracking keeps your entire fleet visible and aligned. It helps you allocate resources more effectively across job sites and reduce unnecessary fuel or labor costs.

How does GPS tracking support equipment maintenance planning?

Trackers monitor engine hours and usage data, making it easier to schedule preventive maintenance before issues arise. This reduces downtime, extends equipment life, and helps you stay ahead of costly repairs.

What types of construction assets can be tracked?

Everything from excavators, bulldozers, and backhoes to trailers, generators, fuel tanks, toolboxes, and even stored materials. If it moves—or needs to stay put—it can be tracked.

How does GPS tracking boost overall project efficiency?

By giving you full visibility into where assets are and how they’re used, GPS tracking helps streamline workflows, reduce equipment idle time, and improve crew coordination. The result? Fewer delays, lower costs, and smoother project execution.