End-to-End Supply Chain Visibility: Your Key to Ending Supply Chain Disruptions

Supply chain disruptions are no longer unexpected setbacks—they’re inevitable obstacles in today’s volatile market. The question isn’t if a crisis will occur, but when and how severely it will impact operations. From geopolitical instability to natural disasters, external risks make it clear that reactive strategies are no longer enough. A Resilinc study found that 76% of supply chain disruptions stem from factors beyond a company’s direct control, reinforcing the need for end-to-end visibility to anticipate and mitigate risks before they escalate.

Rising operational costs, unpredictable delays, and regulatory scrutiny have only intensified these challenges. The ripple effects of trade tensions, geopolitical conflicts, and global events like COVID-19 and last year’s automotive strikes have pushed cross-border transportation costs higher, leading to delays and bottlenecks. At the same time, evolving U.S. trade policies, rising fuel prices, and driver shortages continue to strain logistics networks. These pressures demand more than traditional logistics planning—they require real-time visibility and data-driven decision-making.

End-to-end supply chain visibility is no longer optional—it’s a business imperative. It allows companies to anticipate disruptions, optimize logistics, and enhance customer satisfaction before setbacks become costly. By integrating real-time data, predictive analytics, and GPS tracking, businesses can turn vulnerabilities into competitive advantages. Whether it’s navigating port congestion, optimizing delivery routes, or ensuring cargo security in high-risk environments, a robust GPS tracking system enables companies to remain agile and cost-efficient. The key to success in 2025 and beyond will be proactive investment in supply chain visibility—ensuring businesses not only survive disruptions but thrive despite them.

![]()

What is End-to-End Supply Chain Visibility?

Core Processes of End-to-End Supply Chain Management

As we move through 2025, operations teams like yours are navigating growing complexities. Supply chain disruptions have become the norm rather than the exception, and businesses that lack full visibility into their operations are at a competitive disadvantage.

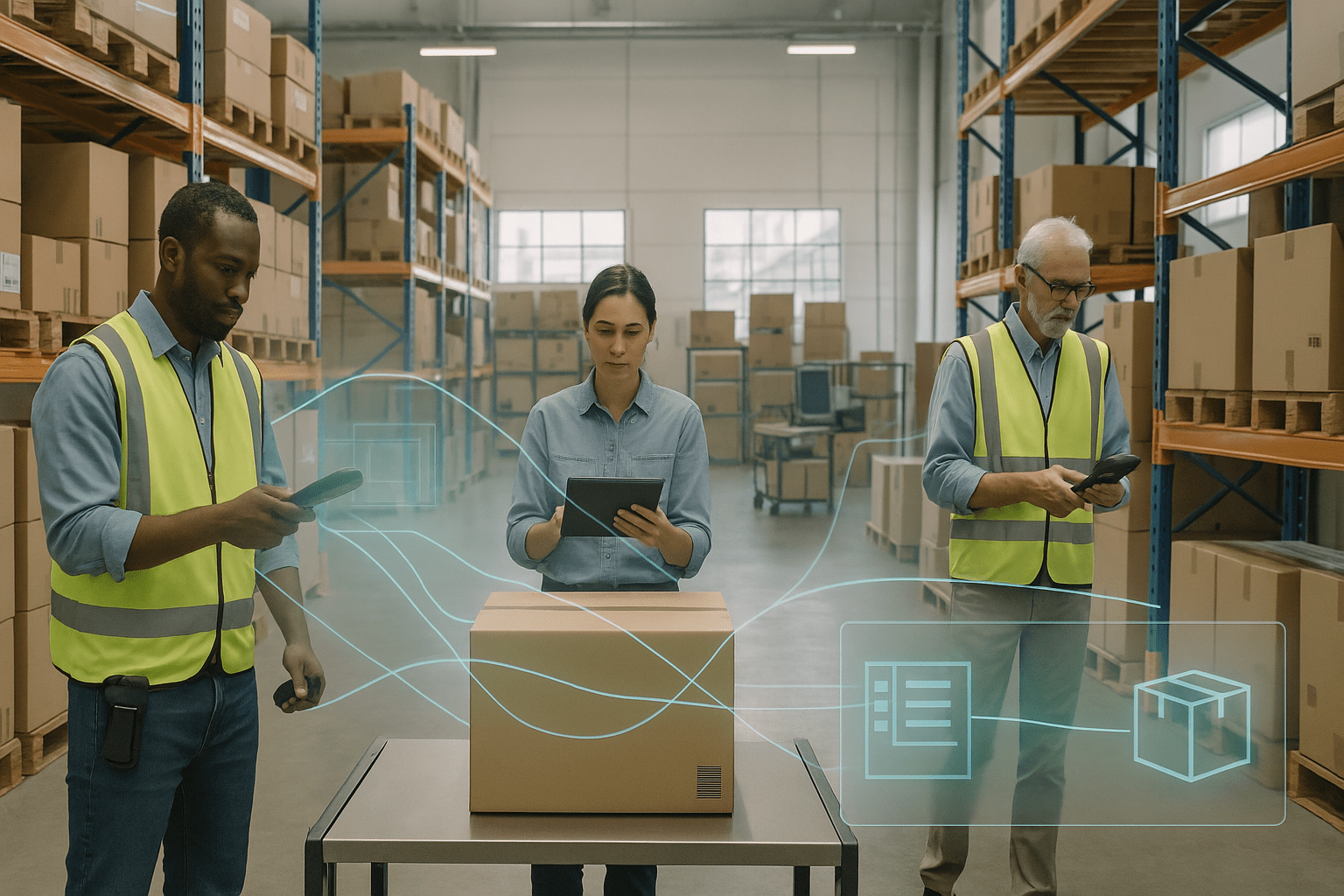

A fully optimized supply chain integrates real-time visibility and strategic automation at every stage. The key steps include:

- 1️⃣ Procurement & Supplier Coordination 📦📑 – Ensuring raw materials arrive on time with supplier performance tracking & predictive analytics.

- 2️⃣ Manufacturing & Production Planning 🏭⚙️ – AI-driven demand forecasting to reduce downtime, waste, and inefficiencies.

- 3️⃣ Inventory Management 📊📍 – Leveraging IoT-powered tracking and RFID/BLE solutions to maintain accurate stock levels, avoiding both overstocking & stockouts.

- 4️⃣ Logistics & Transportation 🚛🗺️ – Implementing GPS-enabled route optimization, smart fleet tracking, and AI-driven forecasting to improve last-mile delivery efficiency and cut fuel costs.

- 5️⃣ Customer Fulfillment & Reverse Logistics 🎯📦 – Accurate ETAs, faster returns, and better post-sale experiences improve customer satisfaction.

E2E supply chain management connects procurement to delivery, enabling real-time tracking, predictive analytics, and seamless data integration for proactive decision-making.

Defining E2E Visibility and the Role of Real-Time Data

Traditional supply chains often operate in silos, where different departments handle their responsibilities independently, leading to inefficiencies and blind spots. E2E visibility means unifying all moving parts into a single, connected ecosystem, where real-time data flows freely across the entire supply chain.

GPS tracking, BLE (Bluetooth Low Energy) mesh networks, and IoT sensors now provide live updates on asset location, condition, and movement, unlike traditional RFID, which requires manual scanning and specific reader infrastructure. GPS and BLE-based tracking work continuously across large, complex environments.

Visibility vs. Transparency: Why It Matters for Businesses

Visibility is about knowing where everything is in real time. Transparency, on the other hand, refers to sharing that visibility with suppliers, logistics partners, and customers to create trust and efficiency. Businesses that master both can reduce delays, optimize routes, and enhance customer satisfaction while keeping their suppliers accountable.

Overcoming End-to-End Supply Chain Challenges

System Integration, Data Security, and Change Management 🔧🔒

Many businesses struggle to integrate modern tracking systems with legacy ERP platforms, leading to data silos and inefficiencies. Without seamless connectivity, valuable real-time insights remain underutilized. The solution lies in leveraging APIs and cloud-based middleware to bridge the gap between existing infrastructure and emerging supply chain technologies. Additionally, automated encryption and cybersecurity protocols must be implemented to safeguard sensitive supply chain data from cyber threats and unauthorized access. However, technology alone isn’t enough—successful implementation requires effective change management strategies, including staff training and stakeholder alignment, to ensure that teams adapt smoothly to new visibility solutions without operational disruptions.

Managing Data Overload, Theft, Complexity, Delays, and Overpromising 📊🔎

With real-time tracking and AI-driven analytics, businesses generate vast amounts of data—but without the right tools, this information can quickly become overwhelming rather than insightful. AI-powered dashboards and predictive analytics help filter out non-essential data, allowing businesses to focus on critical trends and actionable insights. Security is another growing concern, particularly in high-value shipments. GPS and IoT-based theft prevention solutions offer real-time alerts for cargo deviations, significantly reducing the risk of loss or fraud. Additionally, smart logistics platforms enhance efficiency by optimizing delivery schedules, ensuring shipments avoid congestion or other inefficiencies. By aligning people, processes, and technology, businesses can overcome supply chain visibility challenges and create a more agile, cost-effective, and resilient operation.

Key Components for Building Effective E2E SCV: Cloud-Based vs. On-Premise Solutions

Choosing the right infrastructure is critical when implementing end-to-end (E2E) supply chain visibility. Businesses must weigh their options between cloud-based platforms and on-premise systems, considering cost, security, scalability, and operational flexibility.

- 🔹 Cloud-Based Solutions ☁️🌍 – Offer scalability, remote access, and seamless updates. These solutions enable real-time data synchronization across global operations, making them ideal for businesses with multiple locations or those requiring collaboration with external suppliers and logistics partners. Cloud-based systems reduce IT infrastructure costs, enable faster deployment, and provide better accessibility from anywhere in the world.

- 🔹 On-Premise Systems 🔐🏭 – Provide greater control over security and compliance, making them preferable for businesses handling sensitive data or operating in regulated industries such as pharmaceuticals, aerospace, or defense. While they require higher upfront investment and ongoing maintenance, they offer stronger data governance and customization options tailored to specific business needs.

- 🔹 Hybrid Approach 🔄💡 – Many businesses are adopting hybrid models, where cloud analytics complement on-premise tracking infrastructure. This setup allows companies to leverage the flexibility of the cloud for real-time analytics while maintaining critical operations on-premise to ensure security and compliance. Hybrid models provide the best of both worlds—scalability without sacrificing control.

With increasing supply chain complexity, selecting the right infrastructure ensures seamless data flow, optimized operations, and real-time insights, helping businesses stay agile in a rapidly evolving marketplace.

Benefits of Implementing E2E Supply Chain Visibility

A highly visible supply chain provides businesses with the intelligence and agility needed to navigate market uncertainties and disruptions. Key advantages include:

- ✔️ Enhanced Resilience & Risk Management 🚨🛡️ – Identify potential disruptions (e.g., supplier failures, geopolitical tensions, weather-related issues) before they impact operations.

- ✔️ Operational Efficiency & Cost Savings 💰📉 – Reduce waste, transportation costs, and storage expenses.

- ✔️ Better Customer Satisfaction & Loyalty ⭐🤝 – Accurate delivery tracking enhances the customer experience.

- ✔️ Sustainability & Green Practices 🌱♻️ – Optimize supply chain routes, reduce carbon footprint, and minimize excess inventory, aligning with ESG goals.

Businesses with high supply chain visibility experience up to a 20% reduction in logistics costs and a 15% improvement in order fulfillment accuracy, making it a high-ROI investment.

Future Trends in Supply Chain Visibility

Looking ahead, several key trends will reshape supply chain visibility in 2025 and beyond:

- 🚀 AI, Machine Learning & Blockchain 🤖🔗 – AI predicts disruptions, while blockchain secures supply chain data and prevents fraud.

- 📡 5G and Digital Twins 🌐🏗️ – 5G networks will enable real-time data transmission with ultra-low latency, while digital twins will create virtual simulations of supply chains, allowing companies to test and optimize scenarios before making real-world decisions.

- 📦 IoT and Sensor-Based Automation 🌡️📶 – Smart sensors track cargo conditions (temperature, humidity, security) in transit, ensuring product quality.

Final Thoughts: Actionable Steps to Improve Your Supply Chain Visibility Today

Achieving true end-to-end visibility means breaking down silos, integrating real-time tracking, and leveraging predictive analytics. Companies that embrace these solutions will reduce costs, minimize disruptions, and gain a competitive advantage in 2025 and beyond.

Next Steps:

- ✅ Conduct a Supply Chain Audit: Identify blind spots in your current system.

- ✅ Invest in Real-Time Tracking Technology: Implement GPS/BLE tracking for live shipment visibility.

- ✅ Leverage AI & Data Analytics: Use predictive insights to optimize operations and prevent disruptions before they happen.

- ✅ Partner with Experts: Platforms like GPX.co provide cutting-edge tracking solutions tailored to your business needs.

The future of supply chain visibility is here—it’s time to adapt or be left behind.

Frequently Asked Questions (FAQs)

What is end-to-end supply chain visibility and why is it important?

End-to-end supply chain visibility (E2E SCV) provides real-time insights across the entire supply chain, from sourcing to delivery. It helps businesses anticipate risks, optimize operations, and improve decision-making, reducing disruptions and increasing efficiency.

How can E2E SCV help prevent supply chain disruptions?

By integrating real-time data and predictive analytics, E2E SCV helps businesses detect potential bottlenecks, reroute shipments, and adjust procurement strategies before disruptions occur. This proactive approach minimizes delays caused by geopolitical instability, supplier issues, and transportation setbacks.

How does GPS tracking enhance supply chain visibility?

GPS tracking provides real-time location data, optimizes routes, and monitors cargo conditions. When combined with IoT sensors, it offers live updates on shipment status, security breaches, and delays, improving delivery accuracy and reducing operational risks.

What are the common challenges in implementing E2E SCV and how can they be overcome?

Challenges include system integration, data overload, and cybersecurity risks. Solutions include using cloud-based middleware, AI-driven analytics, and secure APIs for seamless connectivity. Change management and staff training ensure smoother adoption and better operational efficiency.

How can AI and machine learning be used for predictive supply chain visibility in 2025?

AI and machine learning predict demand shifts, identify risk patterns, and automate decision-making. By 2025, AI-driven analytics will offer early disruption warnings, optimize inventory, and enhance route planning in real time, making supply chains more agile and efficient.

What is the difference between supply chain visibility and supply chain transparency?

Visibility means having real-time insights into supply chain operations, while transparency involves sharing that data with suppliers, logistics partners, and customers. A business can have visibility without transparency, but both are essential for trust and efficiency.

How does demand forecasting contribute to end-to-end supply chain visibility?

Demand forecasting uses historical data and AI-driven analytics to predict future demand. It helps align inventory and production with market needs, reducing stockouts, overstocking, and delays while improving responsiveness and customer satisfaction.